Stop the Stall on Artificial Intelligence

There are four key areas of focus, broken down by stage, to create a plan that gives you the tools you need to get your applications implemented, adopted and driving bottom-line value to your organization.

1. Preparation

Ensure the right systems are in place to ready your data. Using design thinking and project roadmapping services will validate your data and provide guidance in selecting a vendor that suits your needs.

2. Implementation

Utilize agile project management services to implement your system with the features that you need today and a plan for ones you may need later. Start to build models that illustrate their effectiveness, so you can get your applications running quicker and more efficiently.

3. System Education and Adoption

Train your team on your AI system’s processes through change management services, which facilitates users’ ability to operate your AI without fear of being replaced.

4. Continuous Improvement

Apply data governance services, so as your system collects more data it scales with your organization and keeps tracking key metrics as you evolve.

Finding the right partner is important, as they can concentrate on segments primarily connected to the finance organization.

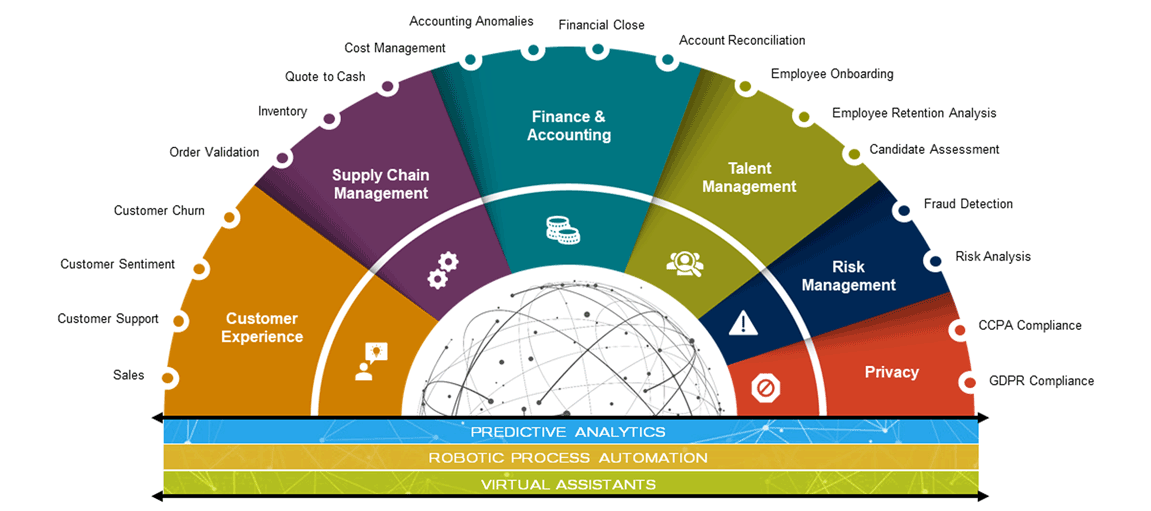

The Spectrum

Your business challenges are unique and require individualized solutions. The spectrum of AI business solutions is built on the foundations of robotic process automation (RPA), predictive analytics and virtual assistants to ensure there is a focus in what can be a sea of AI solutions.

RPA

Allows computers to perform structured digital tasks like a human user following a set of rules. An RPA tool maps a process for a software robot (or bot) to execute, streamlining your organization’s time-consuming, manual processes such as data migration, employee onboarding or expense management. This empowers your team to focus on strategic projects that can help your business grow.

Predictive Analytics

Attempts to understand the future by studying events from the past. Relying on a variety of machine learning algorithms, these systems identify patterns in historical data to provide statistical probabilities of a future event. They can help analyze the lifetime value of a customer, customer churn and other deep learning processes that can increase the effectiveness of marketing campaigns.

Virtual Assistants

Interact with human users to observe behavior and develop insights that can recommend future actions. Tools like chatbots engage with employees and customers by providing targeted information to specific requests. Founded on the underlying technology of natural language processing, these systems can accomplish a variety of functions, including 24/7 customer support, product and service recommendations, internal employee helplines and other cognitive engagement opportunities.

Using just these three tools, you can choose from a host of capable solutions to solve the majority of common business challenges.

Team With Experts

Armanino Intelligence offers digital transformation services and solutions to help organizations improve efficiencies, reduce overhead and establish a competitive advantage against their peers.

Whether you’re considering using AI for the first time or are a seasoned veteran in the space, we offer a comprehensive suite of services to help you successfully integrate AI into your organization. These are organized in three areas that enable you to map an effective strategy, prepare your data for automation and deploy custom applications:

Infographic

Learn how AI can be leveraged to automate key processes, alleviate operational burdens and achieve your specific goals.

View the Infographic

Learn the inside details about how AI is transforming the business world through our insightful discussions with AI industry leaders.

If you’re unsure of how to integrate AI into your organization or need help deploying your project successfully, reach out to our experts to determine the best path forward.